Anti-static raised floor requirements for laying sites

Sources:This site | Release date:

2017-10-16

| Browsing volume:

Key words:Anti-static raised floor requirements for laying sites

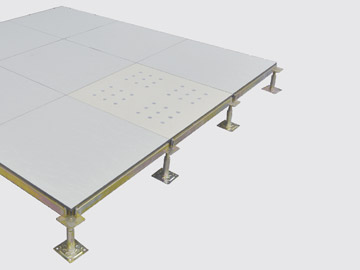

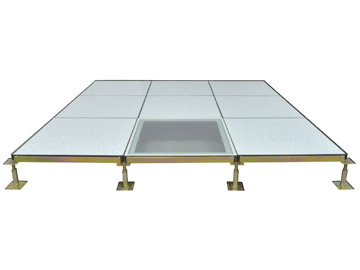

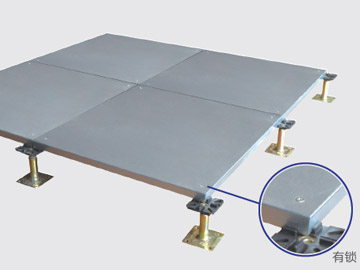

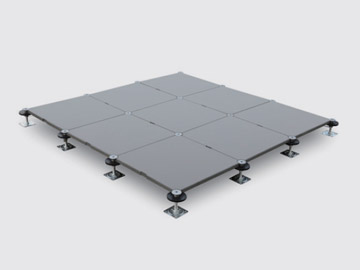

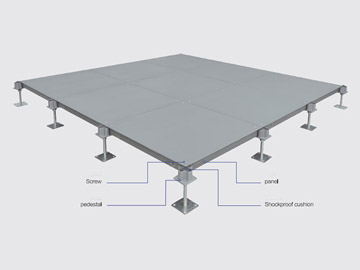

Anti-static raised floor is a kind of building used for paving the ground. Its panel is made of polymer semiconductor material. There is a metal floor under the panel, between the panel and the floor, both are glued and screwed. Connected as a double deck, the panels are mounted on four separate brackets.

Anti-static raised floor can be widely used in electronic computer room, circuit component production workshop, and all places with anti-static requirements. Anti-static raised floor requirements for laying sites:

1. The laying of anti-static raised floor should be carried out after indoor civil works and renovations are completed.

2. Before the laying of the anti-static floor, the floor should be kept flat, dry, free of debris, and free of dust.

3. Before laying the anti-static raised floor, it should be ensured that the cables, circuits, waterways, air and other pipes and air conditioning systems laid under the floor have been completed;

4. Before laying the anti-static floor, ensure that the large-scale heavy equipment base is fixed and the equipment is installed on the base. The height of the base should be the same as the height of the anti-static raised floor surface;

5, anti-static activity floor laying construction site should be equipped with 220V/50Hz power and water.

Please indicate the source of the reprint(Anti-static raised floor requirements for laying sites:/companynews/422)

Relevant articles

Related products

-

GRC Outdoor Raised Access Floor

-

600 wood finished calcium sulphate floor

-

600 ceramic finished raised floor

-

600 Anti-static Calcium Sulphate Floor

-

600 Anti- static access floor

-

600 Calcium Sulphate access floor

-

500 trucking access raised floor

-

GRC raised floor

-

600 All Steel Raised Floor

-

500 All Steel Raised Access Floor